By Margaret Hodson 16′, News Editor

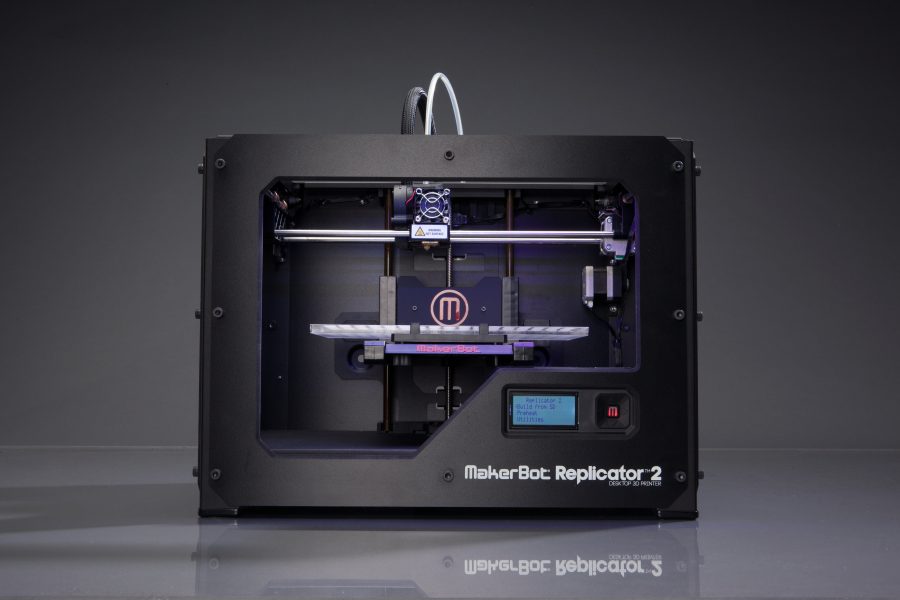

If you thought the Fujitsu tablet was the most cutting-edge technology at Country Day, think again. 3D printing has come to the school. At the beginning of the school year, Country Day purchased a Maker Bot Replicator 2 for $2,000. According to Director of Technology Robert Baker, 3D printing is “definitely the next big thing.” From food to clothing to body parts, 3D printing is revolutionizing the way people design and make products.

As industry leaders around the world experiment with the new technology, Mr. Baker hopes Country Day students can do the same. Some students have already begun using the Maker Bot to print things like iPhone cases and parts for model airplanes. For students interested in using the printer, Mr. Baker hopes to hold an instructional afternoon seminar sometime in the near future.

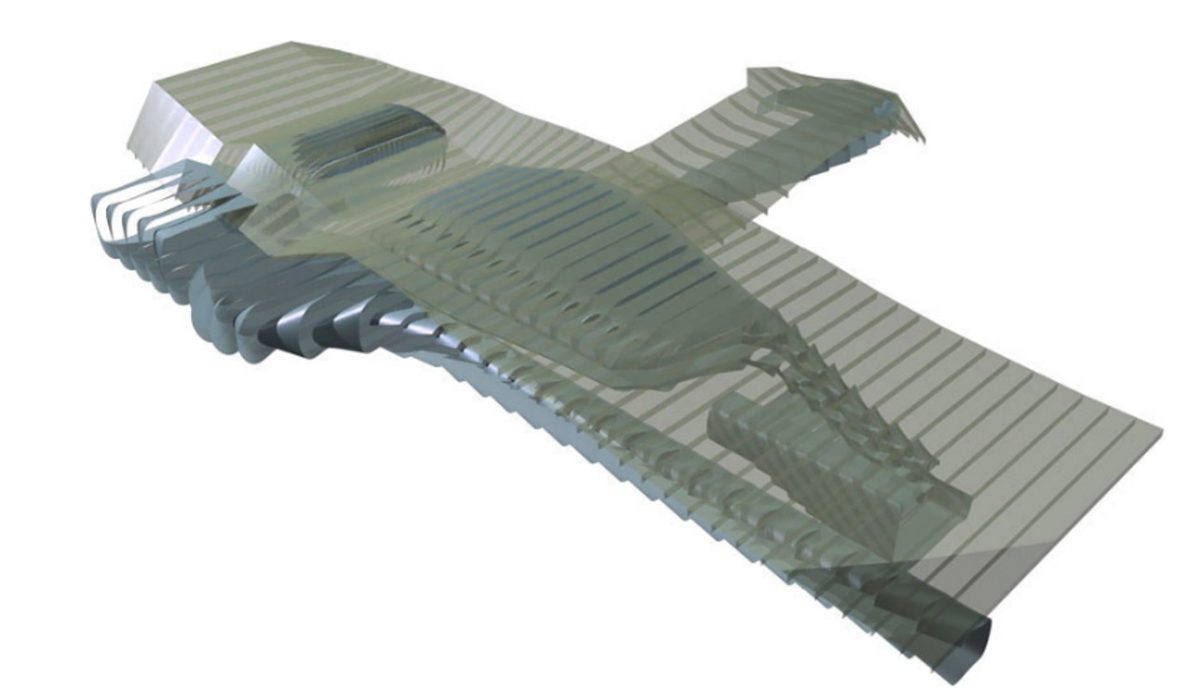

The possibilities of 3D Printing seem limitless. NASA recently funded a 3D printing project to make food for astronauts in space, and the technology has already been used to make pizza and chocolate successfully. GE has been using 3D printers to make airplane engines, and Legacy Effects used a 3D printer to make Tony Stark’s latest Iron Man suit. Fashion designers such as Iris Van Herpen have been designing clothing and accessories, scientists have been experimenting with printing artificial limbs, hip implants, and even blood vessels. The technology allows for a great degree of personalization, which includes complete control over design and the ability to print to scale. Although the use of 3D printing is not yet widespread, the technology has already begun to change the

way prototypes are designed by easily allowing collaboration between design teams on different continents.

To use the Country Day 3D printer, students must first make a 3D rendering of their design. This can be done with many programs including Google SketchUp, a program installed on all students’ tablets. Another 3D modeling program is Sculptress, which allows the user to shape a sphere or plane of clay. Some programs like Autodesk even offer free educational licenses for students. After making a 3D rendering, the file needs to be exported to an STL, which can be done by installing a plugin. The final step is using a program called “Makerware”, which is specific to the Maker Bot Replicator 2 the school owns. The program converts the STL into slices so that the Maker Bot can print the design. It also shows a virtual version of the volume of the printer’s box; the size of the printer’s box is the largest something can be printed. In this way, designs can be scaled so that they are the correct size to be printed. After the design is in the correct file form, the file can be put onto an SD card and subsequently into the printer. Come printing time, the Maker Bot gets up to about 230 degrees Celsius. Depending on the size and complexity of the design, some objects can even take 12 hours to print. The school’s printer is currently equipped with clear plastic, although using colored plastic is also an option.

Regarding planned uses of the technology at Country Day, Mr. Baker said he hopes to incorporate the technology into the classroom, possibly in an engineering or design class. However, for the near future, the focus is on getting the latest and greatest technology into the hands of the students. With the creativity of the student body, the possibilities are really endless. Mr. Baker is excited to see what the students do with the technology, and noted, “I’d like people to be able to hold their creations in their hands.”

Kuang, Cliff. “Iron Man 2’s Secret Sauce: 3-D Printing | Fast Company | Business + Innovation.” Fast Company. N.p., 7 May 2010. Web. 14 Feb. 2014.

Orsini, Lauren. “10 Crazy Things 3D Printers Can Make Today.” ReadWrite. N.p., 14 Feb. 2014. Web. 14 Feb. 2014.

Pithers, Ellie. “Computer Couture: How 3D Printing Could Revolutionise Fashion.” – Telegraph. N.p., 24 July 2014. Web. 14 Feb. 2014.

Replicator2 Press Assets. Digital image. MakerBot. N.p., n.d. Web. 14 Feb. 2014.

Rocha, Coco. “Shapeways Shifts Fashion.” PCMAG. N.p., 14 May 2014. Web. 14 Feb. 2014